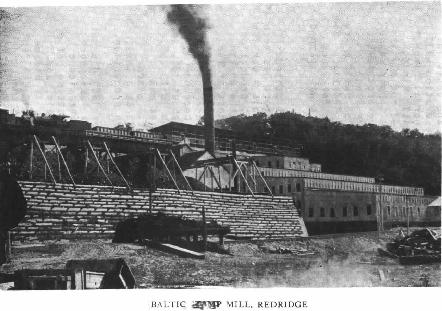

The Baltic Mining Company was organized in December of 1897 and began mining in a section of land directly to the south of land owned by the Atlantic Mine. Seated on the board of directors at the Baltic were also members of Atlantic's board, so when the new company had a need for somewhere to stamp their ore, they naturally turned to Atlantic's stamp mill. In July of 1899 Baltic began stamping test runs of their ore using one head of stamps at the Atlantic mill and continued doing so for the rest of the year. The director's report stated that he thought the stamping could be much improved since they were using an old style head and screens not well suited to their rock.(17) In the mean time a site was chosen for Baltic's own stamp mill on the shore of Lake Superior directly across the Salmon Trout River from the Atlantic mill. When the final bill for the new stamp mill and all supporting structures (including the steel dam, which will be discussed later) was tallied in 1901, Baltic had spent a total of $341,636.28.(18) No fuss was made this time about the cost of construction, as copper prices at this time had boomed and the company needed it's own mill and not a shared one with Atlantic. Access a more detailed 1908 Sanborn representation of the Baltic site here.(38)

The inventory at the mill itself was impressive. Two "Nordberg" steam stamps of special design, and a 150 horse power "Nordberg" tandem compound condensing driving engine were installed, with room for two more as needed. The wash area consisted of 48 jigs and 4 "Wilfey" tables. The boiler house held five 250 horse power "Stirling" water tube boilers which were coal fired. A Green Fuel Economizer was ordered for the site after seeing how well it performed at the Atlantic mill.(19)

Unlike it's counterpart across the river, the Baltic mill underwent some distinct changes over the course of it's lifetime. The mill's two original heads were quickly joined by the two others that had been planned and the four heads were working continuously by 1903. The next year each head was equipped with a 36"X6" Sturtevant roll for treating the oversize from the heads.(20) Baltic also started installing a Huntington Mill and Overstrom tables for saving fine copper, installed a Nordberg-Corliss engine in the boiler house to operate the mechanical draft, triplex boiler feed pump and economizer mechanism. It must be noted that in 1902 the Baltic Mining company became a subsidiary of Copper Range Consolidated, and it is noted in the annual report of that company in 1905 that the Baltic posted higher earnings than any other company in the area with the exception of the Calumet and Hecla, doing it with ore that was only averaging a yield of 22 lbs per ton of ore.(21) An addition to the mill 15'X55' was constructed that year to accommodate storage bins for storage of the copper.

In 1906 another addition was started to accommodate the addition of two new Nordberg steeple compound stamps that were operational within two years. In 1910 a fire severely damaged the boiler house which was fortunately covered by insurance and a new concrete stack 210' tall was constructed between the boiler house and mill. Today this is the only thing of any consequence left of the mill. Find out what else is left by going on a virtual tour of the mill site.

Due to a buildup of tailings right next to the mill, Baltic constructed a mechanical conveyor launder for the mill in 1911 so as to dump the tailings as far away as possible. Also completed that year were a new boiler and superheaters for it, a rail spur to the lake shore and additions to the regrinding plant.(22) It was decided that all the new plants should be powered by a new 1250kW dynamo in the Baltic mill with the excess power being transmitted to Copper Range's other interests in the area. In 1913 a regrinding plant addition to the mill was added to process the richer portion of the mill tailings. Yet another new boiler plant was started in 1915. The final mention of a regrinding addition to the mill is in the 1916 report which stated that the addition was finished and equipment being set up and that the new boiler had been completed.(23) 1916 was also the last year that Baltic Mining Company operated under that name. The next year Copper Range dissolved Baltic and simply called it their Baltic mine operations.

The mill gets no mention at all in Copper Range reports for the next few years and then in 1922 it was finally closed down, sitting idle until 1947 when it was finally dismantled.(24)

The Baltic mill expired from the scene in a more typical way than did the Atlantic.

The main reason for it's demise were rising cost of production, decline of copper

demand, and cutbacks in output from Copper Range mines. This led to most of their

production being concentrated down the road at the newer Champion mill in Freda.