Back to Intro or goto next chapter

Supplemental pages & images referenced in this chapter:

Supplemental pages & images referenced in this chapter:

Site map from Stockholder report

1908 Sanborn representation

A second view of the mill

Atlantic Stamp Mill Operation

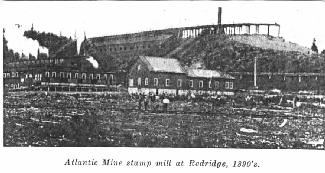

The Atlantic Mining Company had already been in operation for a 23

years before it built it's mill at Redridge. They operated a stamp mill on

the shores of Portage Lake near Cole's Creek for years beforehand. Problems

arose when the War Department of the federal government told the company

that they must either stop dumping the tailings from the stamping process

into the Portage, or erect bulkheads to prevent the tailings from filling

in the shipping channel. The company estimated that a new mill along Lake

Superior would cost up to $100,000 (1), but decided that the increased

output they would get out of the new mill, and elimination of the legal

hassles associated with the Portage site that the expense would be worth it.

Work on the Atlantic Mill was begun as early as 1892 when the land was

purchased and a path for a railroad to the site

(6) from the mine was mapped

out. (Another diagram of the site derived from a 1908 Sanborn map may be seen

here.)

In 1893 Atlantic finished the railroad to the site, cleared and

prepared the area for construction, put up 4 log houses, a barn, rock bins

and started the timber dam which will be discussed in another chapter. It is

interesting to note that a telephone line was run from one of the new houses

back to the mine office at this time for a cost of $413.44 (2). This seems

to indicate very progressive thinking on the part of the company since the

telephone had been invented only about 5 years earlier. In 1894 the mill

was almost completely finished and most of it's equipment installed. In the

report to the stockholders for 1894, the directors included this statement:

It will be remembered that this heavy expenditure has been forced upon us by

the action of the United States Government in forbidding further deposits of

stamp sand in Portage Lake, and could not be avoided if the mine is to be

worked.(3)

Why did they feel the need to reiterate this point? The reason is that in

1894 copper prices had plummeted to an all time low of nine cents per

pound.(4) No doubt the directors were worried that the stockholders would

think they were being wasteful in such a poor market. When the Atlantic

Mill complex was finally completed in 1895, the total amount spent on the

mill and all the supporting structures up to this point came out to

$324,319.69. The equipment in the stamp mill included 6 "Ball" Stamps; one 14"X42" "Reynolds-Corliss" engine; one 14"X7"X12" "Garner" fire pump;

54 iron "Collum" jigs; one 50" "Prentice" drill press; one 18" "Prentice"

lathe; one "Jarecki" pipe bolt and nut cutting machine; one "Daniels"

planer, capacity 24"X24"X25"; jig countershafts for half the mill,

complete, with couplings, pulleys and hangers, and the main line of steam

pipe tapering from 14" in the boiler house to 6" at the far end of the

mill.(5) The boiler house that supplied power to the mill contained five

16'X6' "Evans" fire box boilers which were fired by cordwood. An

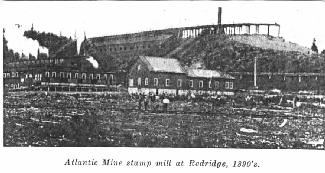

interesting feature of the mill was the design of the smokestack, which

can be seen in the illustration at the beginning of this chapter. Instead

of going straight up off of the ground next to the boiler house, the stack

(measuring 30' tall, 6' in diameter) was placed on the top of the bluff

behind the mill, and a large smoke main 175' long, 7' in diameter was run

up the hill to it. The reports do not state why this was done, but one

theory would be that it was more cost effective than trying to raise a

stack of similar height directly over the boiler house. The mill increased

stamping capacity significantly, but it took quite a while for the company

to take advantage of this due to inadequate hoisting capabilities back at

the mine.

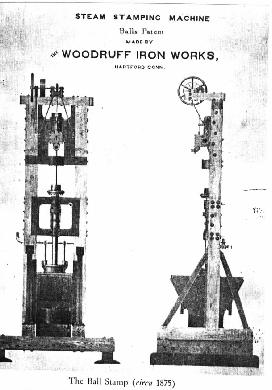

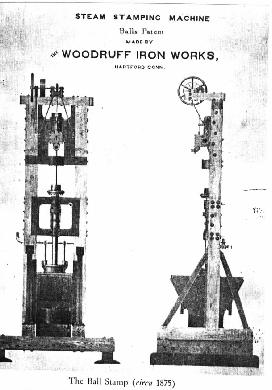

At right is an illustration of the "Ball" Stamp used in the Atlantic Mill.

one 14"X42" "Reynolds-Corliss" engine; one 14"X7"X12" "Garner" fire pump;

54 iron "Collum" jigs; one 50" "Prentice" drill press; one 18" "Prentice"

lathe; one "Jarecki" pipe bolt and nut cutting machine; one "Daniels"

planer, capacity 24"X24"X25"; jig countershafts for half the mill,

complete, with couplings, pulleys and hangers, and the main line of steam

pipe tapering from 14" in the boiler house to 6" at the far end of the

mill.(5) The boiler house that supplied power to the mill contained five

16'X6' "Evans" fire box boilers which were fired by cordwood. An

interesting feature of the mill was the design of the smokestack, which

can be seen in the illustration at the beginning of this chapter. Instead

of going straight up off of the ground next to the boiler house, the stack

(measuring 30' tall, 6' in diameter) was placed on the top of the bluff

behind the mill, and a large smoke main 175' long, 7' in diameter was run

up the hill to it. The reports do not state why this was done, but one

theory would be that it was more cost effective than trying to raise a

stack of similar height directly over the boiler house. The mill increased

stamping capacity significantly, but it took quite a while for the company

to take advantage of this due to inadequate hoisting capabilities back at

the mine.

At right is an illustration of the "Ball" Stamp used in the Atlantic Mill.

In the years that followed the opening of the mill,several modifications

were made to improve performance, but no major structural changes were

made to the mill building itself. Three more boilers were added to the boiler

house to bring the total number to eight, the original number called for in

building specifications. A turntable was placed near the entrance to the

boiler house to help facilitate unloading of fuel. The rock bin trestle at the

terminus of the railroad was lengthened 100 feet to facilitate longer trains.

An electric light plant was added in 1896 which supplied illumination to the

mill, shops, store, and location with 250 incandescent lamps and 6 arc

lamps.(7) In 1897 solid iron foundations were added to 2 of the 6 stamps

to improve their performance. This was later repeated in 1898 for three other

stamps and over the years, the foundations were replaced again, this time

with concrete. A device called a "Green Fuel Economizer" was added to the

boiler plant to increase it's efficiency in 1899. Also that year a line of 3 inch

shafting 200 feet long with friction clutches was put in the mill to operate the

valve gears of the stamps.(8) In 1902 the mill began experiencing problems

in disposing of it's tailings because the launders were no longer high enough.

To remedy the problem the launders were raised and a 5" centrifugal pump

was installed on each head to lift the tailings to the new launder level. At this

time a new heating system was installed and an electrolytic assay laboratory

was installed to determine if they could get further extraction values from their ore.(9)

The year 1903 saw the start of more drastic changes to the way ore

was processed in the mill. Over the course of the next several years the finisher

jigs, slime tables, and round tables were replaced with "Overstrom" Tables. A

Nordberg Corliss engine was also ordered for the purpose of taking the electric

lighting load off of the mill engines.(10) Later on the perforations in the mortar

screens were reduced in order to save more copper. In 1904, the building was

not quite a decade old, but was already showing it's age. The main flue leading

up to the stack needed to be completely replaced and the lower ends of the

wooden posts supporting the structure needed to be replaced with concrete

piers(11), presumably due to the vibrations of the machinery in the building.

1906 marked the beginning of the end for Atlantic Mill. The mill stack

collapsed in April of that year, necessitating replacement.(12) This perhaps was

an omen for the company because in late May the shafts of the Atlantic mine began

to collapse, effectively closing the mine permanently. The mill remained somewhat

busy for the rest of it's lifetime, it was contracted to stamp ore for the Michigan

Copper Mining Company until it could complete it's new mill. It was also used for

Superior ore and test stamping ore taken from a new shaft being explored by the

company. The shipments of Michigan rock were discontinued in late 1909. The

1909 and 1910 reports state that the roof of the mill had been in bad repair and

much work was done to correct this.(13) In 1911 Atlantic Mining Company became

a subsidiary of the Copper Range Consolidated company. The mill continued it's

role of stamping Superior rock until February of 1912. At that time the mill was shut

down, and some cleanup done of the site before it was abandoned.

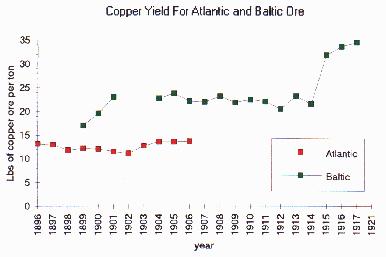

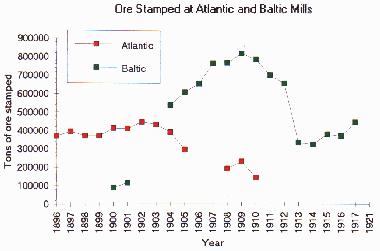

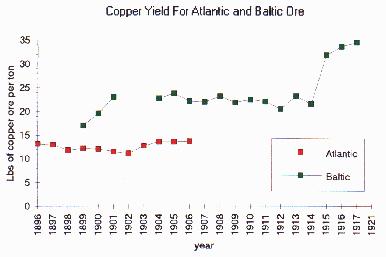

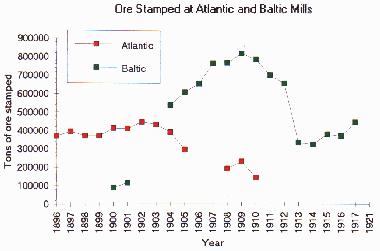

It may seem that the Atlantic mill had a short lifespan, but when one takes a

look at the ore that it was given, it is a wonder that the company lasted as long as it

did. The charts below illustrate the Atlantic's plight relative to the

Baltic Mill.(14) The yield on the ore that Atlantic was bringing up was very poor in

relation to most mines of the era. During the mill's lifetime, the yield on a ton of ore

reached a high of only 13.69 pounds per ton for the year 1906, and a low of 11.095

pounds per ton in 1902, although there were some individual weeks where the yield

would drop to as low as 6.54 pounds per ton.(15) The fact that this company was able

to make a profit on such poor quality ore is a testament to efficient management.(16)

This page hosted by  Get your own Free Home Page

Get your own Free Home Page

one 14"X42" "Reynolds-Corliss" engine; one 14"X7"X12" "Garner" fire pump;

54 iron "Collum" jigs; one 50" "Prentice" drill press; one 18" "Prentice"

lathe; one "Jarecki" pipe bolt and nut cutting machine; one "Daniels"

planer, capacity 24"X24"X25"; jig countershafts for half the mill,

complete, with couplings, pulleys and hangers, and the main line of steam

pipe tapering from 14" in the boiler house to 6" at the far end of the

mill.(5) The boiler house that supplied power to the mill contained five

16'X6' "Evans" fire box boilers which were fired by cordwood. An

interesting feature of the mill was the design of the smokestack, which

can be seen in the illustration at the beginning of this chapter. Instead

of going straight up off of the ground next to the boiler house, the stack

(measuring 30' tall, 6' in diameter) was placed on the top of the bluff

behind the mill, and a large smoke main 175' long, 7' in diameter was run

up the hill to it. The reports do not state why this was done, but one

theory would be that it was more cost effective than trying to raise a

stack of similar height directly over the boiler house. The mill increased

stamping capacity significantly, but it took quite a while for the company

to take advantage of this due to inadequate hoisting capabilities back at

the mine.

At right is an illustration of the "Ball" Stamp used in the Atlantic Mill.

one 14"X42" "Reynolds-Corliss" engine; one 14"X7"X12" "Garner" fire pump;

54 iron "Collum" jigs; one 50" "Prentice" drill press; one 18" "Prentice"

lathe; one "Jarecki" pipe bolt and nut cutting machine; one "Daniels"

planer, capacity 24"X24"X25"; jig countershafts for half the mill,

complete, with couplings, pulleys and hangers, and the main line of steam

pipe tapering from 14" in the boiler house to 6" at the far end of the

mill.(5) The boiler house that supplied power to the mill contained five

16'X6' "Evans" fire box boilers which were fired by cordwood. An

interesting feature of the mill was the design of the smokestack, which

can be seen in the illustration at the beginning of this chapter. Instead

of going straight up off of the ground next to the boiler house, the stack

(measuring 30' tall, 6' in diameter) was placed on the top of the bluff

behind the mill, and a large smoke main 175' long, 7' in diameter was run

up the hill to it. The reports do not state why this was done, but one

theory would be that it was more cost effective than trying to raise a

stack of similar height directly over the boiler house. The mill increased

stamping capacity significantly, but it took quite a while for the company

to take advantage of this due to inadequate hoisting capabilities back at

the mine.

At right is an illustration of the "Ball" Stamp used in the Atlantic Mill.

Supplemental pages & images referenced in this chapter:

Supplemental pages & images referenced in this chapter: