Welcome to Vince Kelly's Carbon Fiber Homepage

You can golf, ride, sail, tennis, drive, cycle, fish, decorate or even

FLY

CARBON FIBER !

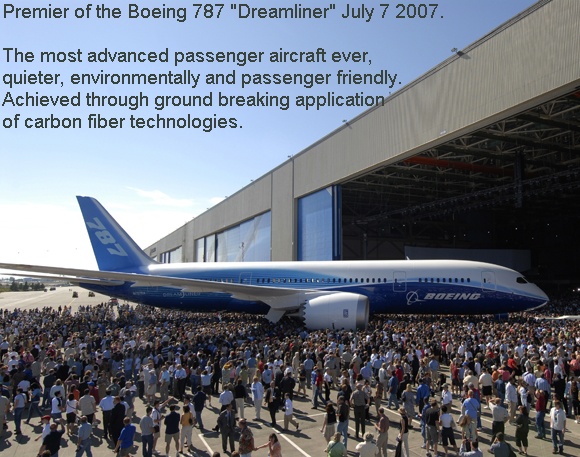

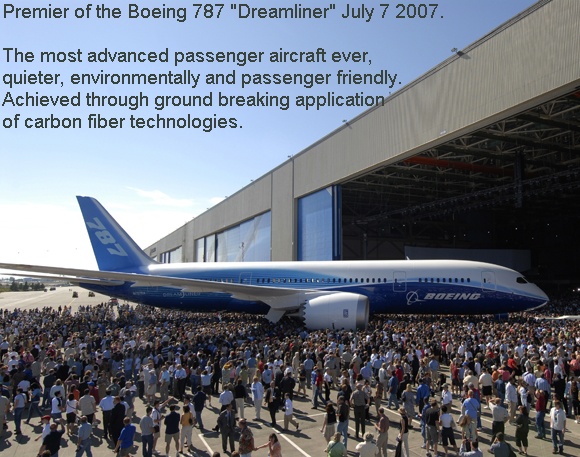

picture courtesy of Boeing, www.boeing.com

You can golf, ride, sail, tennis, drive, cycle, fish, decorate or even

FLY

CARBON FIBER !

Using 20 percent less fuel per passenger than similarly sized airplanes, the 787 is designed for the environment with lower emissions and quieter takeoffs and landings. Inside the airplane, passengers will find cleaner air, bigger windows, more stowage space and improved lighting. Since the 787 program launch in April 2004, Boeing has sold more than 500 airplanes to customers from around the world, passing the 500-airplane order mark faster than any other airplane launch in the history of commercial aviation.

The 787 is the first commercial airplane to make the change from metal to composite structure. The majority of the 787's major structure is made out of composite material. The Dreamliner is the first commercial airplane to be built with a one-piece fuselage. Manufacturing a one-piece fuselage section eliminates 1,500 aluminum sheets and 40,000 to 50,000 fasteners.

Computer generated Images of the new Airbus A350

pictures courtesy of Airbus www.airbus.com

Airbus

A350

The development of this aircraft will see a further significant use of carbon fiber composites.

![]()

Vince Kelly joined the carbon fiber industry in 1981 to research and develop the technology necessary to start up an independent carbon fiber facility in the UK. In 1983 he transferred to a Greenfield site in Scotland, at that time the largest capacity carbon fiber line in Europe. This site is now the home of the carbon fiber manufacturing arm of a German multi-national company.

In 1986 he joined a Dutch multi-national concern in

Germany to start up their new advanced carbon fiber line, purchased under

license from a global manufacturer of advanced polyacrylonitrile (PAN) based

carbon fiber in Japan.

In 2001 he became self employed, focusing in expanding the

application and advanced manufacturing techniques for PAN carbon fibers,

including the following products:

(1)

Advanced high strength carbon fibers in the following yarn sizes (note K

= 1000 filaments) 24K, 12K, 6K, 3K and 1K.

(2)

Specialized carbon fibers such as intermediate and high modulus

grades.

(3) Lower cost carbon fibers 320K, 120K 40K and 24K.

(4)

Evaluation and characterization of various PAN precursor

fibers.

(4)

Specialist products such as oxidized acrylic fibers and activated carbon

fibers.

(5)

Chopped carbon fiber, milled carbon fiber and recycling waste carbon

fiber.

His twenty years+ experience in the carbon fiber business has enabled him to travel the world identifying new markets and business potential for carbon fiber products and technology. Working together with specialists of many year�s experience and in conjunction with world class equipment suppliers we are your premier global source of advanced bespoke carbon fiber technology.

We of

course offer services to users of carbon fiber. Whether you have a new invention

or are an established aerospace company we are able to offer our experience to

help you in product and supplier selection, whether your need is a sample of

fiber or wish to perform a full supplier technology audit, we welcome your

enquiry. We are totally independent. We look

forward to being of service to you.

email vince@carbon-fiber.com

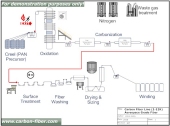

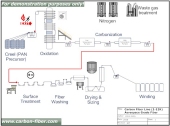

The raw material of PAN, acrylonitrile (AN), is a product of the chemical industry and can be manufactured as follows:

Acrylonitrile (AN) is used as a raw material in acrylic fibers, ABS resin, AS

resin, synthetic rubber (NBR), acrylamide and other materials. Global production

capacity is 4.67 million tons, approximately 60% of which is consumed for

acrylic fibers. In the early manufacturing processes acetylene and hydrogen

cyanide (HCN) were used as a raw material, whereas today nearly all AN is

manufactured using what is called the Sohio process, whereby an ammoxidation

reaction are applied from inexpensive propylene and ammonia. Technological

advances, particularly surrounding research into improved catalysts for the

Sohio process, are proceeding, promoted by a concern for energy conservation and

lessening the environmental loading. The research aims include improved

productivity, reduced byproducts, and lesser wastewater and waste gas.

2. Sohio process

The Sohio process was perfected in 1960 by The

Standard Oil Co. of Ohio, owing to the development of an epoch-making catalyst

that synthesizes AN in a single-stage reaction using propylene and ammonia. The

reaction took place using the fluid-bed od. The P-Mo-Bi group is used as the

catalyst and favorable fluidized conditions are maintained by adjusting the

physical properties of the catalyst.

The reaction gas contains not only AN, but also acetonitrile, hydrogen

cyanide and other byproduct gasses, so AN products are obtained by having the

reaction gas absorbed into water, then using evaporation separation.

5. Improved processes

The Sohio process was epoch-making at the

time it was developed, but improvements have been made in response to the

following conditions:

(1)The AN yield of approximately 60% was not very

high.

(2)The process circulated and used large amounts of water, requiring a

lot of energy.

(3)Approximately 1.5 tons to 2 tons of wastewater was

generated for every ton of AN produced.

(4) Treatment technology for the

waste gas was incomplete.

I. Improved catalyst

II. Steam reduction

Monsanto Corp. improved the water extractive

distillation stage of the Sohio process, reducing the amount of steam required

to produce one ton of AN by three tons.

III. Wastewater and waste gas treatment

AN wastewater normally

contains ammonium sulfate, along with small amounts of nitrile compounds,

hydrocyanic acid and compounds with a high boiling point. Alkali used to be

added to the wastewater before discharging, but nowadays wet oxidation processes

and biological treatment processes are being employed. Bayer Inc. has developed

the technology to recover high-grade ammonium sulfate from the gas generated as

a byproduct of the reaction.

Polymerisation of acrylonitrile produces PAN, the most common carbon fiber

feedstock

The basic unit of PAN is:

OXIDATION involves heating the fibers to around 300 deg C in air. This

evolves hydrogen from the fibers and adds less volatile oxygen.

The polymer changes from a ladder to a stable ring structure, and the fiber changes colour from white though brown to black.

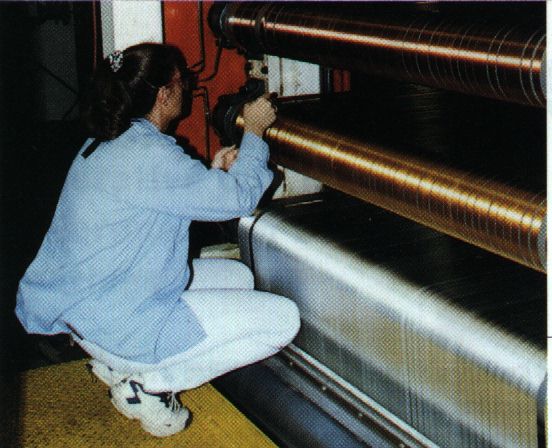

The white PAN strands at the bottom pass through the air heated oven and begin to darken

Quite quickly they turn to black and carbon fiber is like the Ford T, As Henry said "Its any color you want, as long as it's black"

The fatter fibers are not fully oxidized and have a core, which will make a hollow low grade carbon fiber

This shows the importance of a high quality precursor of even cross section

The resulting material is a textile fiber which is fireproof, some companies actually sell this as an end product for example SGL Technic (Scotland), under the tradename PANOX. (OXidised PAN)

The temperature will determine the grade of fiber produced:

| Carbonisation Temperature (�C) | to 1000 | 1000 - 1500 | 1500 - 2000 | 2000 + (Graphitisation) | |

Grade of Carbon Fiber |

Low Modulus | Standard Modulus | Intermediate Modulus | High Modulus | |

|---|---|---|---|---|---|

| Modulus of Elasticity (GPa) | to 200 | 200 - 250 | 250 - 325 | 325 + |

SURFACE TREATMENT forms chemical bonds to the carbon surface, to give a better cohesion to the resin system of the composite

SIZING is a neutral finishing agent (usually epoxy) to protect the fibers during further processing (eg prepregging) and to act as an interface to the resin system of the composite

Carbon fibers are used primarily in composites, these are structures containing two or more components, in the case of fiber reinforced composites this is the fiber and a resin. A composite containing two types of fiber, eg. carbon and glass, is known as a hybrid composite structure. The origins of textile reinforced composites are linked to the development of glass fibers, which commenced in 1938 by the Owens Corning Fiberglass Corporation (USA). Original large scale applications included air filtration, thermal and electrical insulation and the reinforcement of plastics. As the technology of textile reinforced composites expanded, a growing demand from the aerospace industry for composite materials with superior properties emeged. In particular, materials with (1) higher specific strength, (2) higher specific moduli and (3) low density were required. Other desirable properties are good fatigue resistance, and dimensional stability. Carbon fibers were developed to meet this demand.

![]()

Vince Kelly joined the carbon fiber industry in 1981 to research and develop the technology necessary to start up an independent carbon fiber facility in the UK. In 1983 he transferred to a Greenfield site in Scotland, at that time the largest capacity carbon fiber line in Europe. This site is now the home of the carbon fiber manufacturing arm of a German multi-national company.

In 1986 he joined a Dutch multi-national concern in

Germany to start up their new advanced carbon fiber line, purchased under

license from a global manufacturer of advanced polyacrylonitrile (PAN) based

carbon fiber in Japan.

In 2001 he became self employed, focusing in expanding the

application and advanced manufacturing techniques for PAN carbon fibers,

including the following products:

(1)

Advanced high strength carbon fibers in the following yarn sizes (note K

= 1000 filaments) 24K, 12K, 6K, 3K and 1K.

(2)

Specialized carbon fibers such as intermediate and high modulus

grades.

(3) Lower cost carbon fibers 320K, 120K 40K and 24K.

(4)

Evaluation and characterization of various PAN precursor

fibers.

(4)

Specialist products such as oxidized acrylic fibers and activated carbon

fibers.

(5)

Chopped carbon fiber, milled carbon fiber and recycling waste carbon

fiber.

His twenty years+ experience in the carbon fiber business has enabled him to travel the world identifying new markets and business potential for carbon fiber products and technology. Working together with specialists of many year�s experience and in conjunction with world class equipment suppliers we are your premier global source of advanced bespoke carbon fiber technology.

We of

course offer services to users of carbon fiber. Whether you have a new invention

or are an established aerospace company we are able to offer our experience to

help you in product and supplier selection, whether your need is a sample of

fiber or wish to perform a full supplier technology audit, we welcome your

enquiry. We are totally independent. We look

forward to being of service to you.

email vince@carbon-fiber.com

above photos

courtesy of SP Sytems

| Material | Tensile Strength (GPa) | Tensile Modulus (GPa) | Density (g/ccm) | Specific Strength (GPa) | |

| Standard Grade Carbon Fiber | 3.5 | 230.0 | 1.75 | 2.00 | |

|---|---|---|---|---|---|

| High Tensile Steel | 1.3 | 210.0 | 7.87 | 0.17 |

| Material | Tensile Strength (GPa) | Tensile Modulus (GPa) | Density (g/ccm) | Specific Strength (GPa) | |

| Carbon | 3.5 | 230.0 | 1.75 | 2.00 | |

|---|---|---|---|---|---|

| Kevlar | 3.6 | 60.0 | 1.44 | 2.50 | |

| E Glass | 3.4 | 22.0 | 2.60 | 1.31 |

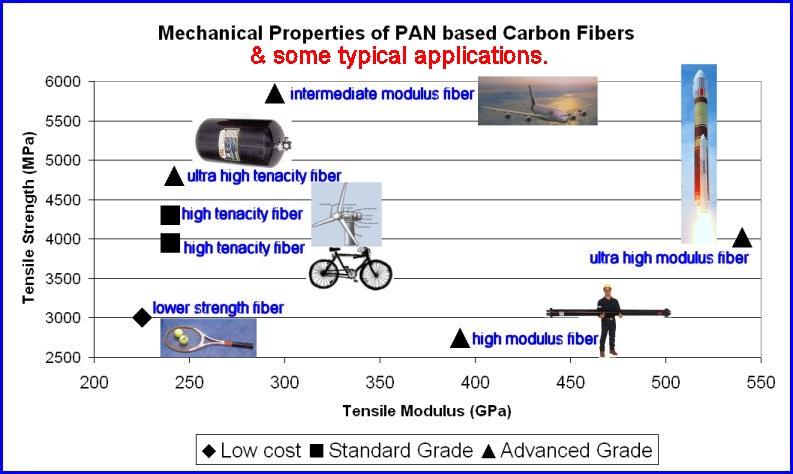

Carbon fibers are also unique in the range of properties that can be found, in this one generic type of material. As most carbon fiber manufactures are working in a state of constant development and improvement, the range of fibers now available to the structural engineer is always changing, look at the developments of the last 15 years:

And

increasingly in more critical parts of the aircraft

Email:vince@carbon-fiber.com

Email:vince@carbon-fiber.com

![]()

Vince Kelly joined the carbon fiber industry in 1981 to research and develop the technology necessary to start up an independent carbon fiber facility in the UK. In 1983 he transferred to a Greenfield site in Scotland, at that time the largest capacity carbon fiber line in Europe. This site is now the home of the carbon fiber manufacturing arm of a German multi-national company.

In 1986 he joined a Dutch multi-national concern in

Germany to start up their new advanced carbon fiber line, purchased under

license from a global manufacturer of advanced polyacrylonitrile (PAN) based

carbon fiber in Japan.

In 2001 he became self employed, focusing in expanding the

application and advanced manufacturing techniques for PAN carbon fibers,

including the following products:

(1)

Advanced high strength carbon fibers in the following yarn sizes (note K

= 1000 filaments) 24K, 12K, 6K, 3K and 1K.

(2)

Specialized carbon fibers such as intermediate and high modulus

grades.

(3) Lower cost carbon fibers 320K, 120K 40K and 24K.

(4)

Evaluation and characterization of various PAN precursor

fibers.

(4)

Specialist products such as oxidized acrylic fibers and activated carbon

fibers.

(5)

Chopped carbon fiber, milled carbon fiber and recycling waste carbon

fiber.

His twenty years+ experience in the carbon fiber business has enabled him to travel the world identifying new markets and business potential for carbon fiber products and technology. Working together with specialists of many year�s experience and in conjunction with world class equipment suppliers we are your premier global source of advanced bespoke carbon fiber technology.

We of

course offer services to users of carbon fiber. Whether you have a new invention

or are an established aerospace company we are able to offer our experience to

help you in product and supplier selection, whether your need is a sample of

fiber or wish to perform a full supplier technology audit, we welcome your

enquiry. We are totally independent. We look

forward to being of service to you.

email vince@carbon-fiber.com